New Technology Developed for Active Vibration Isolation

Active vibration isolation is an essential technology in various industries to effectively reduce the impact of vibrations on sensitive equipment and structures. Recently, a new technology has been developed specifically for active vibration isolation, promising improved performance and versatility. This advancement holds significant potential for enhancing the stability and functionality of critical systems in applications such as aerospace, manufacturing, and research. In this article, we will explore the features and benefits of this innovative technology and its potential impact on various industries.

Active vibration isolation is a technology that utilizes sensors and actuators to counteract unwanted vibrations in various applications, such as precision manufacturing, microscopy, and aerospace. The system continuously monitors vibrations and generates counteracting forces to maintain the position and stability of sensitive equipment. This technology has been developed to provide better performance and adaptability compared to traditional passive isolation systems. It offers improved precision, faster response times, and the ability to handle a wider range of vibration frequencies and amplitudes. Active vibration isolation is becoming increasingly important as the demand for higher precision and stability in various industries continues to grow.

Active vibration isolation is a technology that utilizes sensors and actuators to counteract unwanted vibrations in various applications, such as precision manufacturing, microscopy, and aerospace. The system continuously monitors vibrations and generates counteracting forces to maintain the position and stability of sensitive equipment. This technology has been developed to provide better performance and adaptability compared to traditional passive isolation systems. It offers improved precision, faster response times, and the ability to handle a wider range of vibration frequencies and amplitudes. Active vibration isolation is becoming increasingly important as the demand for higher precision and stability in various industries continues to grow.

1. The Importance of Active Vibration Isolation in Industrial Machinery

Active vibration isolation in industrial machinery is crucial for several reasons. First and foremost, it helps prevent damage to the machinery's components and ensures their longevity. Vibrations can cause wear and tear on machine parts, leading to frequent breakdowns and costly repairs. Additionally, active vibration isolation improves the performance and precision of industrial equipment, ultimately leading to better product quality and increased productivity. Furthermore, it also contributes to a safer working environment by reducing noise and minimizing the risk of accidents caused by excessive machine vibrations. Overall, active vibration isolation plays a significant role in optimizing the efficiency and reliability of industrial machinery.

How Active Vibration Isolation Can Improve Precision Instruments

Active vibration isolation can improve precision instruments by using sensors to detect vibrations and then applying counteracting forces to cancel out the vibrations. This technology helps to keep the instruments stable and precise, allowing for more accurate measurements and operations. It is especially beneficial in environments where there are high levels of vibrations or potential for external disturbances. Additionally, active vibration isolation can also extend the lifespan of precision instruments by reducing wear and tear caused by constant movement and vibrations.

The Role of Active Vibration Isolation in Aerospace Technology

Active vibration isolation plays a crucial role in aerospace technology by reducing the effects of vibrations and shocks on sensitive instruments and equipment. This technology uses sensors and actuators to detect and counteract vibrations in real-time, effectively isolating the payload from the effects of external disturbances. This is particularly important in aerospace applications where precision and reliability are paramount, such as in satellite navigation systems, space telescopes, and research instruments. Active vibration isolation helps to ensure the accuracy and longevity of aerospace equipment, ultimately contributing to the success of missions and scientific discoveries in space.

Implementing Active Vibration Isolation for Sensitive Medical Equipment

Active vibration isolation involves the use of active control systems to counteract vibrations and disturbances in order to protect sensitive medical equipment from potential damage or interference. This is particularly important for equipment such as MRI machines, microscopes, and lasers, which require stable and precise positioning for accurate measurements and diagnoses. The implementation of active vibration isolation typically involves the use of sensors to detect vibrations, and actuators to generate counteracting forces in real time. This can effectively minimize the effects of external vibrations and allow the medical equipment to operate with high accuracy and reliability. In addition to protecting sensitive medical equipment, active vibration isolation can also contribute to improved patient safety and comfort by ensuring the accuracy and reliability of diagnostic and treatment procedures. Overall, implementing active vibration isolation is essential for maintaining the effectiveness and integrity of sensitive medical equipment in healthcare settings.

Active Vibration Isolation: Ensuring Smooth Operation in Automotive Systems

Active vibration isolation is a technology used in automotive systems to minimize the impact of external vibrations on sensitive components. This is achieved through the use of sensors, actuators, and control algorithms to actively compensate for the vibrations and ensure smooth operation of the vehicle. The system constantly monitors the vibrations and applies corrective forces in real-time to counteract the effects. This is particularly important in high-performance vehicles where precision and stability are crucial for optimal performance. Active vibration isolation is used in various automotive applications such as engine mounts, suspension systems, and steering systems to improve ride comfort, handling, and overall vehicle control. This technology plays a critical role in ensuring a smooth and stable driving experience, especially in challenging road conditions or during aggressive driving maneuvers.

Enhancing Performance with Active Vibration Isolation in Robotics

Enhancing robotics performance with active vibration isolation involves the use of various technologies and techniques to minimize the effects of external vibrations on the robot's stability and accuracy. This is achieved through the implementation of active vibration isolation systems that can detect and counteract external vibrations in real-time, thus improving the overall performance of the robot. These systems typically utilize sensors to measure vibrations, as well as actuators and control algorithms to actively mitigate the effects of these vibrations on the robot's operation. By effectively isolating the robot from external vibrations, its precision, reliability, and overall performance can be significantly enhanced, making it better suited for demanding applications in industrial, research, and other settings.

Active Vibration Isolation Solutions for Renewable Energy Technologies

Active vibration isolation solutions for renewable energy technologies involve the use of advanced control systems and actuators to mitigate the effects of vibrations on equipment such as wind turbines, solar panels, and wave energy converters. These systems are designed to actively monitor and counteract the forces and vibrations that can lead to wear and tear, reduced performance, and increased maintenance costs. By implementing active vibration isolation solutions, renewable energy technologies can operate more reliably and efficiently, ultimately contributing to the growth of the sustainable energy market.

The Future of Active Vibration Isolation in Advanced Engineering

Active vibration isolation is an emerging technology that seeks to minimize the effects of vibrations on engineered systems. It involves the use of sensors and actuators to detect and counteract incoming vibrations in real-time, resulting in improved performance and longevity of sensitive equipment. In advanced engineering, this technology holds promise for applications in precision manufacturing, aerospace, defense, and medical imaging, among others. As the technology continues to develop, it is expected to play a crucial role in enabling the design and operation of increasingly complex and sensitive engineering systems. Key areas of research and development in this field include the optimization of sensor and actuator configurations, real-time control algorithms, and the integration of active vibration isolation with other advanced engineering technologies. Overall, the future of active vibration isolation in advanced engineering is characterized by the potential for significant advancements in performance, reliability, and overall system integration.

In conclusion, the new technology developed for active vibration isolation offers promising solutions for minimizing the impact of vibrations on sensitive equipment and structures. Through the use of advanced control systems and smart materials, active vibration isolation provides an effective means of ensuring stability and precision in a wide range of applications. Active vibration isolation has the potential to greatly improve the performance and longevity of critical equipment, making it a valuable tool in the field of engineering and technology.

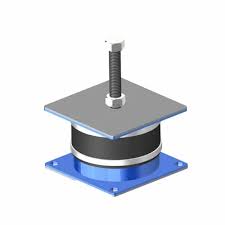

seismic vibration isolators

See also

https://www.mason-ind.com/products/vibration-isolators/ https://www.airloc.com/en/products/vibration-isolation/

Comments

Post a Comment